Unlocking Potential: The Journey Through a Paddy Processing Plant

In the heart of expansive rice fields, where golden grains sway gently in the breeze, lies the unsung hero of an intricate agricultural journey—the paddy processing plant. This facility, often overlooked in the romance of rural landscapes, plays a pivotal role in transforming humble paddy into the staple food that nourishes millions. As grains are transported from field to factory, they embark on a fascinating journey filled with innovation, precision, and a deep respect for tradition. In this article, we invite you to explore the inner workings of a paddy processing plant, revealing the complex processes and dedicated individuals that unlock the potential of rice. From the initial stages of milling to the final packaging, join us as we delve into the mechanisms that ensure quality and sustainability, bridging the gap between farm and table. Prepare to discover not just the transformation of rice, but also the stories that thread through each grain, connecting communities and cultures across the globe.

Exploring the Lifecycle of Paddy: From Field to Fork

As we delve into the intricate journey of paddy from the verdant fields to the processing plant, we witness a transformation that encapsulates the essence of agriculture. The lifecycle begins with the careful cultivation of paddy, where farmers select the best strain suited to local conditions. Water management is crucial, and it is here, amid rich, flooded fields, that paddy plants flourish. Throughout this initial phase, farmers attend to essential tasks such as:

- Seeding – Sowing seeds at the correct time ensures optimal growth.

- Irrigation - Maintaining water levels promotes healthy root systems.

- Weeding - Regularly removing invasive weeds preserves the nutrient supply to the plants.

Once harvested, paddy heads towards the processing plant, where technology meets tradition. It undergoes a series of meticulously designed stages that enhance quality while preserving flavor. The process typically involves:

| Stage | Description |

|---|---|

| Hulling | The outer husk is removed to reveal brown rice. |

| Polishing | Further refining to create white rice that gleams. |

| Packaging | Final products are weighed and packaged for distribution. |

This transformation not only increases the shelf-life of rice but also enhances its appeal on grocery store shelves, bringing a product that is vital to diets around the world. Understanding these processes highlights the challenges and innovations in the paddy industry, paving the way for sustainable practices that honor both the earth and the consumer.

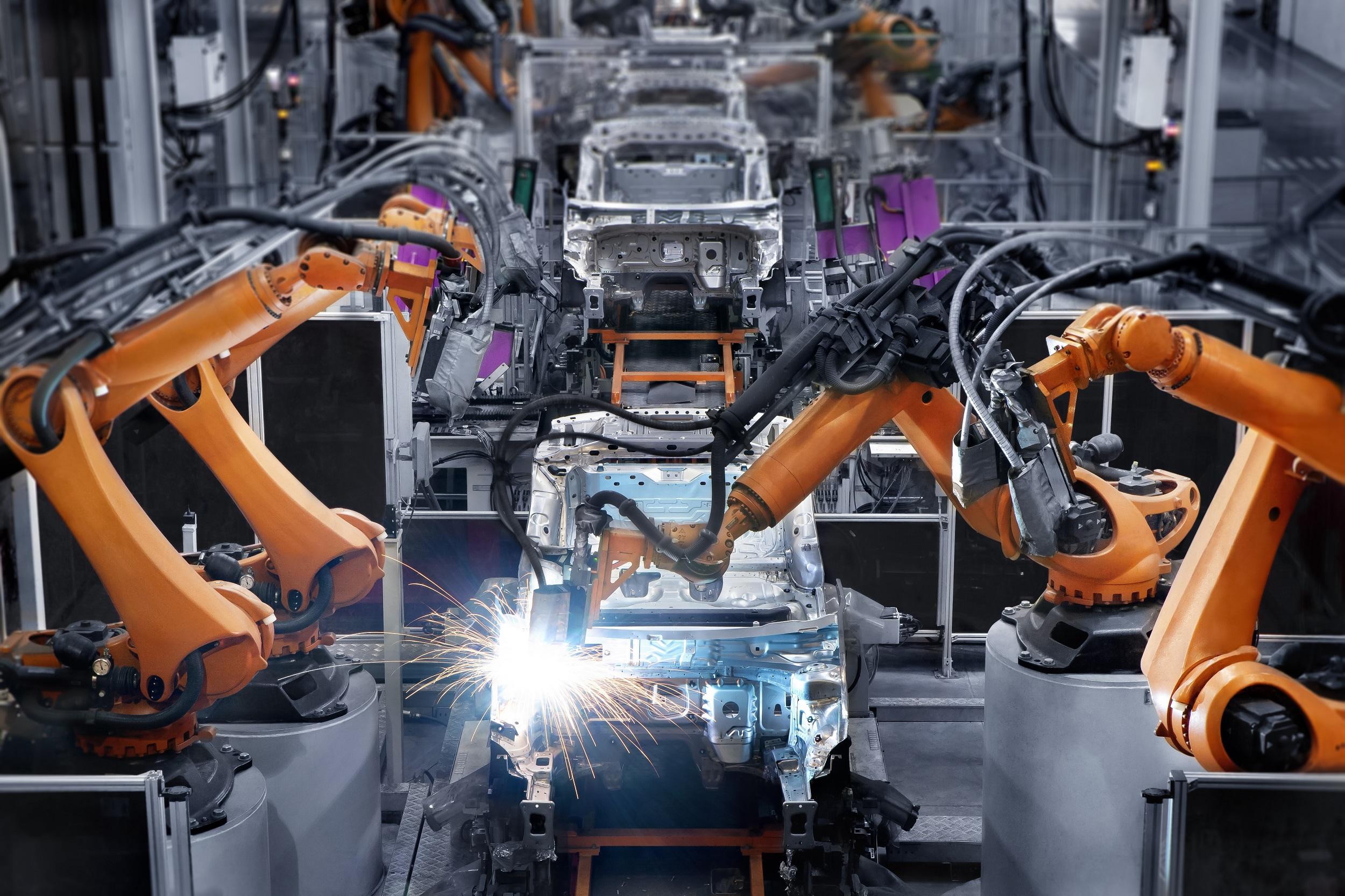

Understanding the Machinery: Innovations in Paddy Processing

The world of paddy processing has witnessed remarkable advancements that not only enhance efficiency but also improve the quality of rice produced. At the heart of these innovations lies a range of sophisticated machinery designed to streamline each stage of the process. From pre-cleaning to milling, modern equipment incorporates cutting-edge technology that minimizes losses and maximizes output. Key machines include:

- Pre-cleaners: These machines remove impurities such as stones and dust before milling begins, ensuring a cleaner raw product.

- Hullers: Specially designed to separate the husk from the grain, hullers contribute significantly to yield efficiency.

- Milling Machines: Utilizing advanced grinding techniques, these machines produce higher quality rice with better texture and taste.

- Color Sorters: Employing optical sensors, these devices ensure only the best grains make it to the final product, discarding discolored or defective rice.

Moreover, automation has transformed operational workflows, enabling real-time monitoring and data analytics to enhance decision-making. The integration of IoT technology allows for seamless communication between machinery components, improving both performance and maintenance. The following table illustrates the significant reductions in waste and improvements in output achieved through such technologies:

| Method | Waste Reduction (%) | Output Improvement (%) |

|---|---|---|

| Conventional Processing | 15 | 70 |

| Automated Systems | 5 | 90 |

This interplay of technology and agricultural practices signifies a leap forward in paddy processing, allowing producers to unlock the full potential of their harvests while meeting the growing global demand for quality rice.

Quality Control Practices: Ensuring Excellence at Every Stage

At the heart of a paddy processing plant lies a systematic approach to ensure that quality is never compromised. Implementing robust quality control practices throughout the operation guarantees that every grain processed reaches its potential. This journey begins at raw material selection, where only the finest paddy is sourced to create the foundation for quality. Continuous monitoring is crucial, as it sets the stage for each phase of processing. Key practices include:

- Visual Inspections: Conducting routine checks for impurities and discolorations.

- Moisture Testing: Ensuring optimal moisture levels to prevent spoilage and maintain flavor.

- Laboratory Analysis: Testing samples for nutritional content and contaminants.

Once the paddy moves through the various stages of processing—from cleaning to milling—each step demands precision and diligence. Incorporating checkpoints such as instant feedback loops and data analytics plays a significant role in refining these stages. For instance, the milling process leverages advanced technology to monitor grain integrity and minimize breakage. Below is a summary table showcasing the key quality control measures and their respective benefits:

| Quality Control Measure | Benefit |

|---|---|

| Cleaning Procedures | Removes foreign materials, increasing purity. |

| Regular Calibration | Ensures equipment accuracy, reducing errors. |

| End-Product Testing | Verifies adherence to quality standards. |

Sustainability Initiatives: Balancing Production with Environmental Responsibility

In the heart of our paddy processing plant, where the rhythmic clatter of machinery meets the gentle rustle of grain, sustainability is woven into the very fabric of our operations. Our commitment to environmental responsibility drives us to implement practices that not only enhance production but also protect the ecosystem. From sourcing raw materials to the final packaging, we engage in strategies such as:

- Water Conservation: Employing closed-loop systems to minimize water waste during the washing and soaking processes.

- Energy Efficiency: Investing in solar panels and energy-efficient machinery to reduce our carbon footprint.

- Waste Reduction: Utilizing by-products for animal feed and composting residues to create natural fertilizers.

Moreover, we continuously seek innovative methods to balance productivity with ecological stewardship. Our team collaborates with local farmers to implement sustainable agricultural practices, ensuring that the paddy is cultivated in a manner that preserves soil health and biodiversity. This partnership is essential for:

| Practice | Impact |

|---|---|

| Crop Rotation | Enhances soil nutrients and reduces pest prevalence. |

| Organic Fertilizers | Minimizes chemical runoff and promotes a healthier ecosystem. |

| Diverse Planting | Increases resilience against climate variability. |

Through these combined efforts, we strive to create a model of sustainability that not only meets the demands of a growing market but also fosters a healthy planet for future generations.

Final Thoughts

As our exploration of the paddy processing plant comes to a close, we find ourselves reflecting on the intricate dance between nature and technology that fosters the transformation of humble grains into vital sustenance. Each step of the journey— from the golden fields to the rhythmic hum of machinery—whispers stories of tradition, innovation, and the relentless pursuit of excellence.

In unlocking the potential of paddy, we not only reveal the complex processes behind rice production but also shine a light on the dedication of countless hands that work tirelessly to nourish our world. This journey reminds us that agriculture, while deeply rooted in history, is also a canvas for creativity and advancement.

As we leave the plant, we carry with us an appreciation for the unseen efforts that shape our meals and our planet. The path through the processing plant is not just a passage of grains but a testament to the collective endeavor that sustains us. With every kernel, we are reminded of our shared responsibility to honor and support these journeys—both in our daily lives and through the innovations we embrace for the future.