In the heart of rural landscapes and bustling urban centers alike, a humble yet vital process unfolds—maize milling. This intricate dance of grain transformation encompasses centuries of tradition, innovation, and resilience, shaping not only the culinary experiences of communities but also their economies and cultures. From golden fields swaying in the breeze to the rhythmic hum of industrial machinery, the journey of maize from ear to flour is a story woven with the threads of science and history. In this article, we delve into the fascinating world of maize milling, uncovering the secrets behind this age-old craft and exploring its significance in today’s global food landscape. Join us as we peel back the layers of this staple grain, illuminating the processes, techniques, and technologies that turn simple maize into a versatile ingredient beloved around the world.

Understanding the Maize Milling Process and Its Importance

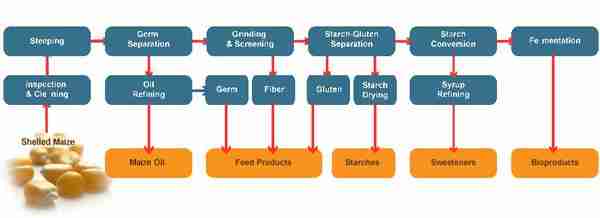

The maize milling process is a fascinating journey that transforms a humble grain into a variety of essential products. At the heart of this process lies the careful selection of maize kernels, which are cleaned and conditioned to ensure optimal milling efficiency. Traditionally, the first step involves removing impurities such as dust, stones, and other foreign materials, followed by a soaking process that enhances the moisture level of the kernels. This conditioning helps to achieve a high-quality end product by standardizing the milling characteristics and preventing breakage during grinding. Once prepared, the maize is subjected to a series of grinding and sieving steps that reduce the grain into flour or meal, depending on desired particle size and texture.

The importance of maize milling cannot be overstated, as it plays a critical role in the food supply chain. The milled maize products are widely used in various culinary applications, making them staples in diets around the world. From breakfast cereals, tortillas, and polenta to snacks and baked goods, milled maize serves a multifunctional role in nutrition and cuisine. Additionally, maize milling supports agricultural economies by providing farmers with access to markets for their harvested grains, helping to improve livelihoods and foster sustainable practices in rural communities. Understanding this process reveals not just the science of grain transformation, but also its broader implications on food security and cultural heritage.

| Maize Milling Stages | Purpose |

|---|---|

| Cleaning | Remove impurities to ensure quality |

| Conditioning | Prepare kernels for milling |

| Grinding | Reduce kernels to flour or meal |

| Sieving | Achieve the desired particle size |

Key Technologies and Equipment in Modern Maize Milling

In the intricate process of maize milling, several key technologies and equipment play critical roles in transforming raw maize into versatile flour products. One of the most essential machines is the corn grinder, designed to crush the grains into finer particles effectively. Coupled with roller mills, which utilize pairs of heavy cylindrical rolls to further refine and reduce the particle size, these machines ensure uniformity in texture and quality. Moreover, sifters are pivotal in this phase, separating different particle sizes to achieve the desired flour consistency, allowing for the production of various grade flours tailored for diverse culinary needs.

Another innovation enhancing maize milling is the use of air classifiers, which leverage air flow to separate granules based on size and weight, ensuring optimal quality control. Additionally, degermination machines excel in removing the germ from maize, a crucial step if the end product requires increased shelf life and reduced oil content. To streamline operations, modern plants also incorporate automated control systems, enabling real-time monitoring of processes and ensuring high efficiency while reducing labor costs. The integration of these advanced technologies not only accelerates the milling process but also enhances the overall quality and nutritional value of the maize products.

Health and Nutrition: The Impact of Milling on Maize Quality

The journey from maize to flour is not merely a transformation in texture; it significantly influences the nutritional profile of the grain. Milling, depending on the method used, determines the extent of nutrient retention and the overall quality of the final product. For instance, wet milling often preserves valuable components like starch and protein, while dry milling can strip away important nutrients, particularly in the outer layers of the grain where fiber and essential vitamins reside. The quality of maize flour can vary widely based on the milling technique employed, leading to potential disparities in health benefits for consumers.

Beyond the milling process itself, the variety of maize also plays a crucial role in nutritional outcomes. Different types may contain varying levels of essential nutrients such as carotenoids, which are vital for eye health, and phytochemicals that promote overall wellness. A comparative look at processed maize products reveals distinct differences in nutrient density:

| Maize Product | Protein Content (%) | Fiber Content (g/100g) | Calcium Content (mg/100g) |

|---|---|---|---|

| Whole Grain Maize Flour | 8 | 7 | 11 |

| White Maize Flour | 6 | 2 | 8 |

| Yellow Maize Flour | 7 | 3 | 10 |

It is essential for consumers to be aware of the milling practices and varieties available in the market, as these factors contribute significantly to their dietary choices. Informed selections can lead to better health outcomes, highlighting the underlying significance of milling in the broader context of food nutrition.

Sustainable Practices in Maize Milling for a Greener Future

In the quest for a more sustainable future, maize milling has begun to embrace practices that prioritize environmental stewardship while enhancing productivity. The focus is shifting toward reducing the ecological footprint of milling operations through innovative techniques and responsible resource management. Key initiatives include the adoption of energy-efficient machinery, use of renewable energy sources, and the implementation of waste minimization strategies. By investing in technology that conserves energy and reduces water usage, milling facilities can significantly lessen their environmental impact while also lowering operational costs.

Moreover, the integration of byproduct utilization and recycling into maize milling processes exemplifies a holistic approach to sustainability. By repurposing husks and bran into animal feed or biofuel, mills not only cut down on waste but also contribute to a circular economy.

Consider the following ways milling operations can enhance their sustainability:

- Water Recycling: Implementing systems that treat and reuse water used in the milling process.

- Responsible Sourcing: Partnering with local farmers who utilize sustainable agricultural practices.

- Energy Recovery: Installing systems that capture heat generated during milling for other uses.

| Practice | Impact |

|---|---|

| Energy-efficient Machinery | Reduces energy consumption by up to 30%. |

| Byproduct Utilization | Minimizes waste and creates additional revenue streams. |

| Water Recycling Systems | Decreases water usage by 50% or more. |

These measures not only reflect a commitment to sustainability but also resonate with consumers increasingly drawn to environmentally conscious products. By embracing sustainable practices, the maize milling industry has the potential to lead the way towards a greener future, ensuring that the benefits of innovation extend beyond the mill, positively impacting communities and ecosystems alike.

Insights and Conclusions

As we conclude our journey through the intricate world of maize milling, we find ourselves standing at the intersection of tradition and innovation. The transformation of this humble grain into a myriad of food products is not merely a process; it is an art form steeped in history and science. From the rhythmic turning of grinding stones to the modern precision of automated machinery, each step reveals the dedication of millers who honor the legacy of those before them while embracing the future.

Understanding the secrets of maize milling equips us with a deeper appreciation for the foods that grace our tables. Each bite of freshly baked bread, every spoonful of porridge, reflects the countless hours spent perfecting the craft of grain processing. As we navigate the complexities of this essential industry, let us carry forward the knowledge and respect for the meticulous work behind each kernel.

In a world where food choices are abundant, recognizing the journey of maize—from field to flour—reminds us to value the labor, innovation, and sustainability that uphold our cherished culinary traditions. As we bid farewell to this exploration, may we remain curious and inspired to delve deeper into the stories that shape our food, one grain at a time.