In the world of breakfast foods, few items are as universally beloved as cereal. It has managed to captivate generations with its convenient crunch and delightful array of flavors, making morning routines a little brighter and more enjoyable. But have you ever paused to consider the journey that each flake or puff takes before it lands in your bowl? Beyond its colorful packaging and catchy mascots lies a fascinating story of innovation and precision—one that involves complex processes and a blend of science and art.

In “Unraveling the Secrets of Cereal Processing: A Comprehensive Guide,” we will delve deep into the intriguing world of cereal production, exploring the various stages from ingredient selection to the final packaging. This guide aims to uncover the techniques and technologies employed by manufacturers to create the textures and tastes we find irresistible. By demystifying the enigmatic processes behind cereal processing, we invite you to gain a fresh perspective on this staple’s journey and its significance in our daily lives. So pour yourself a bowl, grab a spoon, and let’s embark on this enlightening exploration together.

Understanding the Cereal Processing Lifecycle and Its Impact on Quality

The journey of cereals from field to table is a complex tapestry woven with various stages of processing that directly influence their quality. Each step—harvesting, drying, milling, and storage—plays a critical role in ensuring that the final product meets consumer expectations. Understanding this lifecycle is essential for both producers and consumers alike. Key factors affecting the quality of cereals include:

- Harvesting Time: The timing of harvest can affect moisture levels, which in turn influences the grain’s shelf life.

- Drying Methods: Traditional sun drying vs. mechanical drying can lead to differences in taste and nutrient retention.

- Milling Techniques: Different milling processes, such as stone milling and modern roller milling, yield varying textures and flavors.

- Storage Conditions: Temperature and humidity control can prevent spoilage and maintain freshness.

A deeper dive into the processing stages reveals how specialized technologies and practices can enhance quality. For instance, precision harvesting ensures that grains are picked at optimal ripeness, significantly improving flavor and nutritional value. Furthermore, assessing quality metrics during milling—such as particle size distribution—can lead to better end products that cater to consumer preferences. This table summarizes the impact of various processing methods on cereal quality:

| Processing Method | Impact on Quality |

|---|---|

| Mechanical Drying | Reduces moisture quickly, preserving nutrients |

| Stone Milling | Retains flavor and nutritional compounds |

| Cold Storage | Minimizes spoilage and maintains texture |

By appreciating the intricacies of cereal processing, stakeholders can make informed decisions to enhance the quality of cereals, ultimately leading to a more satisfying experience for consumers and a sustainable future for producers.

Key Techniques in Cereal Processing: From Milling to Extrusion

Cereal processing is an intricate dance of techniques designed to transform raw grains into the versatile foods we enjoy. At the heart of this transformation lies milling, the pivotal step where whole grains are ground into flour. This process not only affects the texture and flavor but also influences the nutritional profile. The art of milling can be categorized into several methods, including stone milling, hammer milling, and roller milling. Each method has its unique advantages and applications, and choosing the right technique enhances both quality and efficiency.

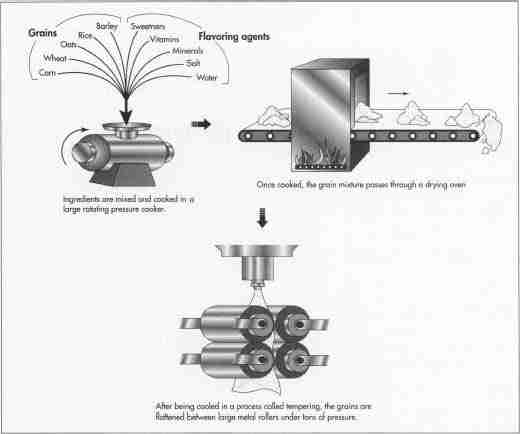

Moving beyond milling, extrusion plays a crucial role in cereal processing, particularly for snack production and breakfast cereals. This high-temperature, short-time process involves forcing a mixture through a die under pressure, resulting in uniquely shaped and textured food products. The benefits of extrusion include improved digestibility, enhanced flavor release, and the ability to incorporate various ingredients seamlessly. Key parameters in this process include moisture content, temperature, and feed rate, which collectively dictate the final product’s characteristics. Below is a brief overview of the factors impacting both milling and extrusion:

| Technique | Key Factors | Impact on Product |

|---|---|---|

| Milling | Method, Speed, Moisture | Texture, Flavor, Nutritional Value |

| Extrusion | Moisture, Temperature, Feed Rate | Shape, Crispiness, Flavor |

Nutritional Enhancements: Fortification Strategies in Cereal Production

In the quest for improved health outcomes, cereal production has embraced nutritional enhancements through innovative fortification strategies. These methods aim to elevate the nutritional profile of cereals, making them not just staples, but also powerful allies in combating micronutrient deficiencies. When implemented effectively, fortification can encompass a range of vitamins and minerals that may otherwise be absent in common diets. Some of the key nutrients often integrated during processing include:

- Iron: Essential for hemoglobin production.

- Folic Acid: Crucial for cell division and preventing neural tube defects.

- Zinc: Plays a vital role in immune function and growth.

- Vitamin D: Important for bone health and immune response.

When embarking on a cereal fortification program, manufacturers face a myriad of options for the method of enhancement. Options range from blending to extrusion and even spray-drying, each with its unique benefits and challenges. Understanding the behavior of various nutrients during processing is key to maintaining their efficacy. To illustrate the effectiveness and application of different fortification strategies, the table below presents a comparative overview:

| Fortification Method | Advantages | Considerations |

|---|---|---|

| Direct Addition | Simple and cost-effective | Potential nutrient loss during storage |

| Encapsulation | Protects sensitive nutrients during processing | May increase production costs |

| Coating | Allows for controlled release of nutrients | Requires specialized equipment |

Sustainability Practices in Cereal Processing: Balancing Efficiency and Environmental Responsibility

The evolution of cereal processing has given rise to innovative practices aimed at enhancing sustainability while maintaining operational efficiency. Key methods employed in the industry include:

- Water Conservation: Utilizing closed-loop systems minimizes water waste during processing.

- Energy Efficiency: Implementing energy recovery systems harnesses heat from production processes, reducing overall energy consumption.

- Sustainable Sourcing: Prioritizing local and organic grain suppliers helps mitigate transportation emissions and supports local economies.

- Waste Reduction: Byproducts of cereal processing are repurposed for animal feed or composting, minimizing landfill contributions.

Furthermore, the integration of technology plays a significant role in enhancing sustainable practices. Automation and data analytics provide insights that enable businesses to fine-tune their processes, striking a balance between productivity and environmental impact. Consider the following benefits of technological integration:

| Technology | Benefit |

|---|---|

| Smart Sensors | Monitor resource use and optimize processing parameters in real-time. |

| Blockchain | Enhance traceability in sourcing and ensure sustainable practices throughout the supply chain. |

| AI Analytics | Predict demand and adjust production schedules to reduce waste. |

In Retrospect

As we reach the end of our exploration into the intricate world of cereal processing, it’s clear that beneath the seemingly simple crinkle of a cereal box lies a deeply complex journey. From the fields where grains are harvested to the state-of-the-art facilities that transform raw ingredients into the breakfast favorites we cherish, every step plays a pivotal role in shaping the final product. Understanding these processes not only enriches our appreciation for what fills our bowls each morning but also invites us to consider the broader implications for health, sustainability, and innovation in the food industry.

So, the next time you pour your cereal, take a moment to reflect on the craftsmanship and science behind those crunchy morsels. We’ve unraveled the secrets of cereal processing, shedding light on an often-overlooked industry that quietly impacts our daily lives. Knowledge is power, and with this newfound understanding, we can make more informed choices about our food and, perhaps, inspire conversations around the future of cereal and nutrition. Thank you for joining us on this enlightening journey; may your mornings be ever crunchy and your bowls ever full!