In the world of culinary excellence, rice is not just a staple; it’s a canvas, waiting to be transformed by the art of cooking. Yet, before it graces our plates, an often-overlooked process shapes its character and flavor: polishing. Recent advancements in jet rice polishing technology are redefining this crucial stage, promising to elevate the quality and taste of rice to unprecedented heights. As we embark on this exploration of “Unlocking Precision: The Future of Jet Rice Polishing,” we will delve into the innovative techniques and scientific principles that are paving the way for a new era in rice production. From improving grain texture to enhancing nutritional value, the future of rice polishing promises to not only preserve the heritage of this beloved grain but also to enhance its role in global cuisine. Join us on this journey to discover how precision and innovation are set to revolutionize the way we perceive and enjoy one of the world’s oldest food sources.

The Evolution of Jet Rice Polishing Technology

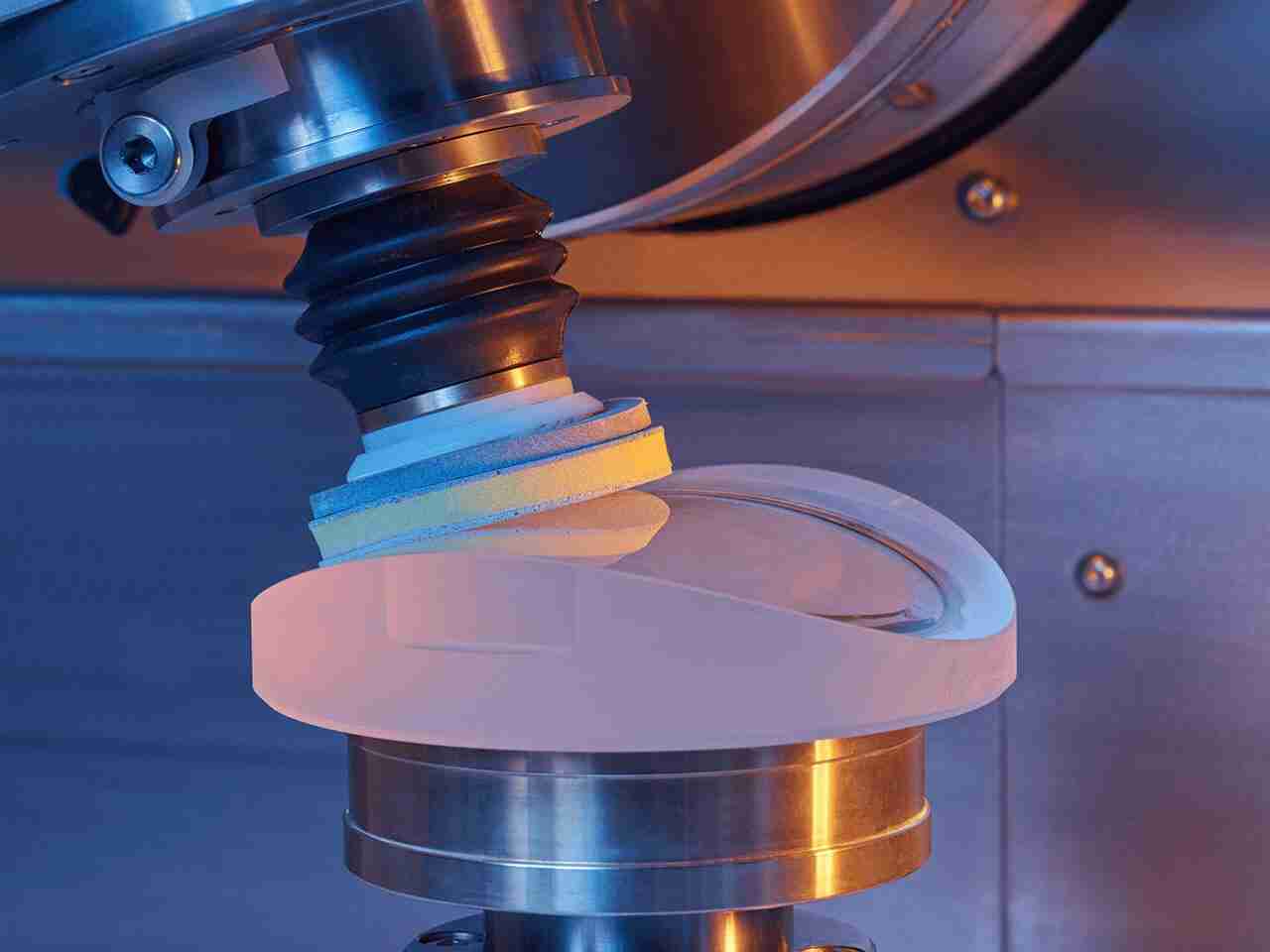

The journey of jet rice polishing technology has seen remarkable transformations over the decades, significantly enhancing the quality and yield of rice production. Early methods relied heavily on mechanical polishing, which often resulted in the loss of crucial nutrients and a decline in grain integrity. However, with the advent of jet polishing, rice milling transitioned to a more sophisticated approach, utilizing high-speed air jets to gently remove the outer layers of the rice kernel. This method not only preserves the essential nutrients but also helps in achieving a smoother, more visually appealing product.

Today’s innovations continue to push the boundaries of jet rice polishing, integrating advanced features like AI-driven analytics and smart temperature controls to ensure optimal results. Some of the key developments in this evolution include:

- Eco-friendly Polishing Solutions: Minimizing environmental impact through sustainable practices.

- Enhanced Grain Protection: Reduced breakage and improved quality through precision engineering.

- Customized Polishing Settings: Tailored processing for different rice varieties to meet varied consumer demands.

To illustrate the advancements, consider the comparison of traditional methods versus modern jet polishing technology:

| Feature | Traditional Methods | Jet Polishing Technology |

|---|---|---|

| Nutrient Retention | Low | High |

| Breakage Rate | Higher | Lower |

| Processing Time | Longer | Shorter |

Understanding the Benefits of Precision Polishing for Quality

Precision polishing has emerged as a game-changer in the agricultural sector, particularly in the processing of jet rice. This advanced technique enhances not only the appearance but also the overall quality of the grains, ensuring a superior final product. By utilizing specialized machinery and techniques, precision polishing effectively reduces the outer layer of rice while preserving essential nutrients. The meticulous approach facilitates a smoother texture and improved cooking quality, thus meeting consumer preferences for visually appealing and palatable rice.

The benefits of integrating precision polishing into rice processing are manifold:

- Enhanced Nutritional Value: Retaining vital nutrients while improving grain appearance.

- Improved Shelf Life: Polished rice remains fresh longer due to reduced surface moisture.

- Increased Marketability: A visually appealing product attracts consumers, leading to higher sales.

- Efficient Processing: Streamlined operations reduce waste, maximizing overall productivity.

To illustrate the effectiveness of precision polishing, the following table showcases the difference in quality between traditionally milled rice and precision-polished jet rice:

| Quality Aspect | Traditionally Milled Rice | Precision-Polished Jet Rice |

|---|---|---|

| Appearance | Matte, uneven | Shiny, uniform |

| Nutrient Retention | Lower | Higher |

| Cooking Quality | Variable texture | Consistent, smooth |

These advancements not only enhance consumer experience but also set a new standard for quality in the rice industry. By adopting precision polishing methods, producers can ensure their products are more appealing and beneficial to the health-conscious market, ultimately paving the way for a brighter future in rice processing.

Exploring Sustainable Practices in Rice Processing

In the rapidly evolving landscape of rice processing, sustainable practices are gaining traction as industry leaders strive to minimize their environmental impact. By implementing innovative technologies, such as precision polishing techniques, rice mills can significantly reduce waste while enhancing the quality of the final product. Sustainable processing not only meets the growing consumer demand for eco-friendly products but also provides a competitive edge in the market. The integration of energy-efficient machinery and techniques can lead to notable reductions in water consumption and greenhouse gas emissions, aligning with global sustainability goals.

Among the most promising advancements is the adaptation of jet polishing, which leverages advanced airflow mechanics. This method surpasses traditional polishing by:

- Minimizing grain breakage: Reducing the physical impact on rice kernels.

- Enhancing energy efficiency: Utilizing targeted air jets that require less power.

- Lowering water usage: Achieving optimal polishing without excessive rinsing.

To illustrate the sustainability benefits associated with jet rice polishing, consider the following comparative table:

| Process Type | Energy Consumption | Water Usage | Grain Breakage Rate |

|---|---|---|---|

| Traditional Polishing | High | Moderate | 10% |

| Jet Polishing | Low | Minimal | 2% |

This concise comparison highlights how embracing innovation can contribute to a more sustainable future for rice processing, ensuring that both producers and consumers can benefit from a responsible approach to agricultural production.

Future Innovations in Jet Rice Polishing Techniques

As the demand for high-quality rice increases, so does the need for innovative jet rice polishing techniques that enhance grain quality while minimizing waste. Advanced jet polishing systems are emerging, utilizing precision-engineered jets to remove bran without compromising the integrity of the rice kernel. These systems leverage cutting-edge technology, such as:

- AI-Driven Control Systems: Utilizing machine learning algorithms to regulate polishing pressures and durations, ensuring optimal results.

- Eco-Friendly Abrasives: Implementing natural abrasives that effectively polish the surface while reducing environmental impact.

- Smart Monitoring Sensors: Incorporating IoT technology to monitor moisture levels, enabling real-time adjustments for superior outcomes.

Looking ahead, sustainability and efficiency are paramount. Manufacturers are exploring the integration of renewable energy sources into jet polishing operations. Furthermore, innovations like recyclable polishing materials can substantially decrease the carbon footprint of rice processing. A visionary approach would focus on establishing circular economy principles within the rice milling industry, leading to a paradigm shift in how rice is polished. The following table highlights some anticipated key advancements:

| Innovation | Description | Benefits |

|---|---|---|

| AI-Enhanced Automation | Use of AI for predictive maintenance and optimal polishing parameters | Reduces downtime, ensures consistent quality |

| Waterless Polishing | Techniques that minimize or eliminate water usage | Conserves resources, environmentally friendly |

| Integrated Waste Recovery Systems | Systems designed to repurpose bran and other byproducts | Improves sustainability, creates additional revenue streams |

The Conclusion

As we soar into the future of culinary innovation, the evolution of jet rice polishing stands poised at the intersection of tradition and technology. By unlocking unparalleled precision in this age-old process, we have the opportunity to not only enhance the quality and flavor of rice but also to elevate the entire dining experience. The advancements in jet polishing not only promise to redefine our expectations of rice but also invite us to consider the broader implications of precision in food preparation and sustainability.

In this brave new world, precision is not merely a technical achievement; it’s a pathway to better nutrition, reduced waste, and a renewed appreciation for the art of cooking. As researchers, chefs, and engineers collaborate to refine these techniques, it’s essential that we view jet rice polishing not just as a technological marvel but as a cultural evolution that honors the grains’ rich heritage.

As we turn our gaze towards this exciting horizon, let us embrace the potential of jet rice polishing—the perfect blend of science and gastronomy—where every grain tells a story, and every meal crafted is a celebration of innovation. The future is polished, and it awaits our exploration.