In a world where efficiency reigns supreme, the agricultural sector is primed for transformation. At the heart of this change lies rice milling—an age-old practice that serves as a cornerstone for food security and economic stability in many regions. As demand for high-quality rice surges amid global population growth, the conventional methods of milling are increasingly being scrutinized for their effectiveness and sustainability. Enter the era of combined rice milling, a revolutionary approach that melds innovation with tradition. This article explores the potential of combined rice milling to unlock new levels of efficiency, reduce waste, and reshape the future of rice production. Join us as we delve into the emerging technologies, processes, and strategies that promise to redefine an industry and benefit farmers, consumers, and the environment alike.

Transforming Traditional Processes into Smart Innovations

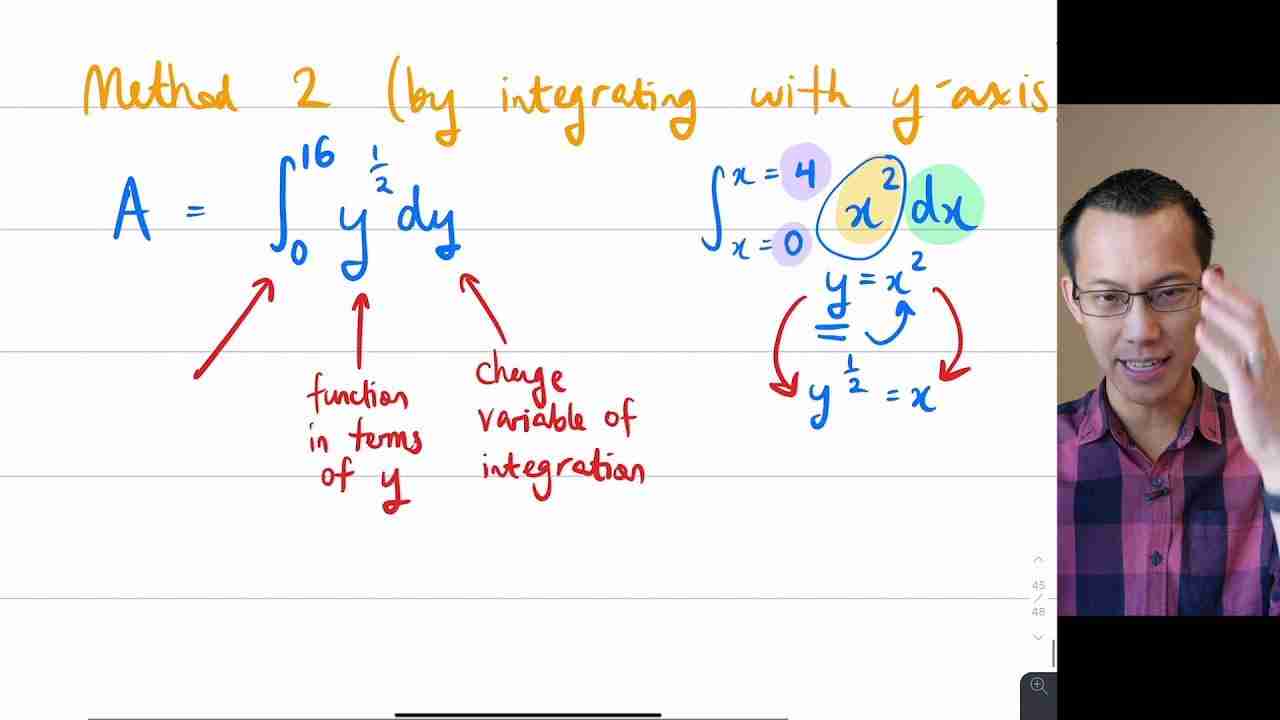

In the world of agriculture, traditional methods often hold farmers back from realizing their full potential. As the demand for high-quality rice increases, integrating advanced technologies into rice milling processes offers a beacon of hope for efficiency and productivity. By harnessing smart innovations, traditional milling can evolve from a labor-intensive practice to an automated, streamlined operation. For instance, the incorporation of artificial intelligence can optimize the milling process, ensuring minimal waste and maximized output. Moreover, real-time data analytics can provide insights into quality control, enabling millers to maintain superior standards that satisfy consumer preferences.

The transformation extends beyond just technological integration; it involves a holistic approach that combines various modern practices. Farmers and millers can benefit from a smart supply chain, ensuring that the entire process—from harvesting to milling—is interconnected. Here are several key components that contribute to this evolution:

- Automated Equipment: Reduces human errors and enhances precision.

- IoT Sensors: Monitor moisture levels and quality throughout the milling process.

- Blockchain Technology: Ensures traceability and transparency in the supply chain.

By focusing on these innovations, rice milling can not only enhance efficiency but also contribute to sustainable agricultural practices. The following table outlines the key benefits associated with this transformation:

| Benefit | Description |

|---|---|

| Increased Productivity | Automation leads to faster processing times. |

| Higher Quality | Consistent monitoring improves product standards. |

| Sustainability | Less waste promotes environmental responsibility. |

Integrating Sustainability Practices in Rice Milling Techniques

Incorporating environmentally friendly practices in rice milling not only contributes to sustainability but also enhances productivity and operational efficiency. One innovative approach involves the adoption of energy-efficient machinery that utilizes renewable resources. These modern machines, designed with advanced technology, lead to reduced energy consumption and lower greenhouse gas emissions. Furthermore, waste management strategies play a pivotal role in sustainable rice milling. By implementing circular economy principles, leftover biomass from the milling process can be transformed into valuable by-products, such as organic fertilizers or biofuels, minimizing waste and fostering resource recovery.

Additionally, water conservation techniques are essential in modern rice milling operations. Techniques such as recycling water within the milling process, along with the use of water-efficient systems, significantly reduce water usage and prevent pollution of local waterways. The integration of precision milling technology can also result in less rice husk and bran loss, ensuring that the maximum amount of grain is processed efficiently. To encapsulate these practices, the following table highlights a few sustainable techniques gained popularity within the industry:

| Technique | Benefit |

|---|---|

| Energy-Efficient Machinery | Reduces energy consumption |

| Waste-to-Value Initiatives | Transforms waste into by-products |

| Water Recycling Systems | Minimizes overall water usage |

| Precision Milling | Maximizes grain recovery |

Enhancing Quality Control Through Technological Advancements

The integration of cutting-edge technologies into quality control systems is revolutionizing the rice milling industry. Automation, data analytics, and artificial intelligence pave the way for enhanced precision and consistency. Sensors and cameras can detect impurities and inconsistencies in real-time, leading to immediate corrective actions. By ensuring that only the highest quality grains reach the final product, businesses can reduce waste and improve customer satisfaction. This technological infusion allows for continuous monitoring, detecting issues far earlier than traditional methods would permit.

Furthermore, advancements in machine learning algorithms facilitate better predictive analytics, enabling mills to anticipate potential quality issues before they occur. By analyzing vast datasets from various milling processes, these systems can identify patterns and suggest optimal adjustments. The result is a more efficient operation that minimizes downtime and maximizes output. Adopting these innovative strategies not only enhances quality control but also leads to sustainable practices, ensuring a reduction in resource consumption throughout the milling process.

Strategies for Strengthening Supply Chain Resilience in Rice Production

To navigate the complexities of rice production, it is essential to leverage a multifaceted approach for enhancing resilience in the supply chain. One key strategy is to diversify sourcing by developing multiple supplier relationships. This reduces dependency on a single source and mitigates risks associated with supply disruptions. Additionally, implementing advanced forecasting technologies allows producers to better predict demand fluctuations and adjust their production accordingly. By integrating data analytics with real-time market insights, stakeholders can optimize resource allocation and minimize waste.

Another crucial aspect is the promotion of sustainable practices throughout the rice production lifecycle. This includes investing in eco-friendly technologies for water management and soil health, ensuring quality yields while preserving the environment. Establishing collaborative networks among farmers, suppliers, and distributors can also enhance communication and streamline logistics. By creating transparent channels for information sharing, all parties can respond swiftly to changing market conditions. A supportive framework that includes training and access to resources can empower local producers, ultimately reinforcing the entire rice supply chain against unforeseen challenges.

In Retrospect

the future of combined rice milling promises to redefine efficiency in grain processing, ushering in an era where resource conservation and technological advancement go hand in hand. As we explore new innovations and sustainable practices, the industry stands on the brink of a transformation that not only meets the demands of a growing population but also prioritizes environmental stewardship. By embracing smart technologies and optimizing processes, stakeholders can enhance yields and reduce waste, paving the way for a more productive and sustainable rice supply chain. As we look ahead, it is clear that the path to unlocking efficiency will be paved with collaboration, creativity, and a commitment to embracing the agricultural solutions of tomorrow. Together, we can cultivate a future where food security and sustainability thrive in harmony.