From Kernel to Flour: The Art of Maize Milling Explained

In the vibrant tapestry of the culinary world, few ingredients hold as much significance as maize. This versatile grain, cherished across cultures and continents, transforms not only our plates but also our understanding of food production. Yet, behind every soft tortilla, delicate cornbread, and hearty polenta lies a meticulous process that often goes unnoticed: milling. The journey from shiny, golden kernels to the fine, powdery flour is an art form steeped in tradition, innovation, and precision. In this exploration, we delve into the fascinating world of maize milling, unraveling the techniques and technologies that breathe life into this staple ingredient. Join us as we trace the steps of this time-honored craft, discovering the nuances of each phase of milling and celebrating the intrinsic value of maize flour in our kitchens and beyond.

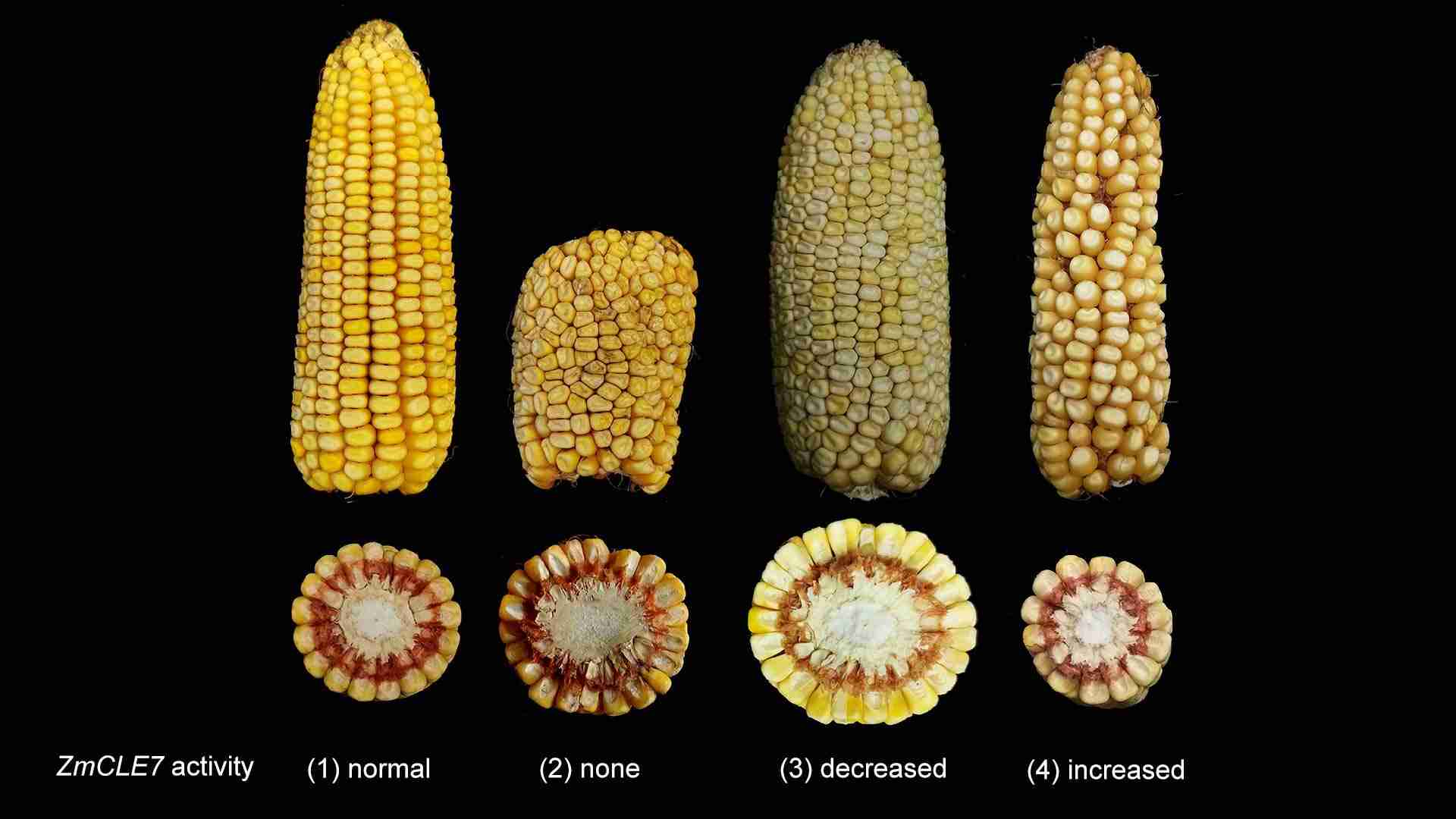

Understanding the Maize Kernel: Varietal Differences and Their Impact on Milling

The maize kernel is a marvel of nature, embodying a variety of physiological characteristics that influence its milling behavior and flour quality. Different varieties of maize, each with their unique genetic makeup, demonstrate distinct features such as kernel hardness, kernel color, and starch content. These attributes not only define the end product but also determine the effectiveness of various milling techniques. For instance, dent corn, known for its softer texture and high starch content, often yields a finer flour ideal for baking, while flint corn, with its hard exterior, is capable of producing coarser flour, suitable for grits or polenta.

The impact of these varietal differences extends beyond merely the milling process; it can also influence the flavor, aroma, and nutritional profile of the final flour. The table below summarizes some common maize varieties and their milling implications:

| Maize Variety | Characteristics | Milling Result |

|---|---|---|

| Dent Corn | Soft, high starch | Fine flour, excellent for baking |

| Flint Corn | Hard, lower starch | Coarser flour, great for grits |

| Sweet Corn | High sugar content | Flavorful flour, used in specialty products |

The Milling Process Unveiled: Techniques and Equipment for Optimal Flour Extraction

The maize milling process is a remarkable blend of art and science, transforming whole kernels into fine flour through carefully orchestrated techniques and specialized equipment. At the heart of this process is preparation, which involves cleaning the maize to eliminate impurities and foreign materials, followed by conditioning the grains. Conditioning requires the precise addition of moisture to the kernels, allowing them to soften and ensuring optimal grinding results. The moisture content is crucial, as it affects the milling efficiency and quality of the final product.

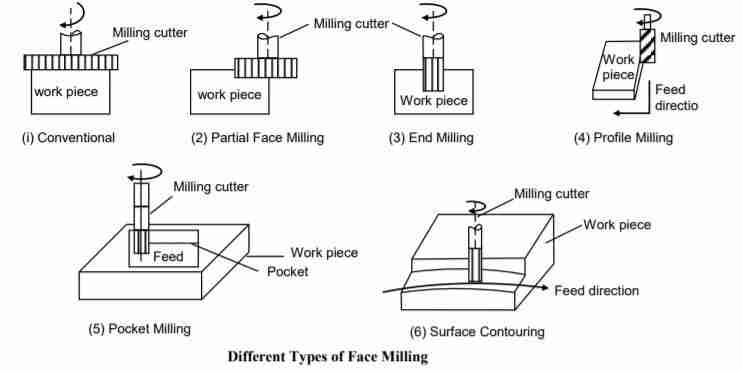

Once conditioned, the maize undergoes grinding, where the kernels are crushed between rotating stones or metal rollers. This step can be categorized into various techniques, including:

- Stone milling, which is traditional and provides a coarser flour texture.

- Roller milling, widely used for finer flour, consists of multiple passes through increasingly finer rollers.

- Air classification, which separates the flour based on particle size and weight, resulting in a consistent product.

The extraction rate of flour from maize can be influenced by the milling technique employed. In essence, this process ensures that flour retains maximum nutritional value while achieving the desired fineness and texture.

| Technique | Description | Extraction Rate |

|---|---|---|

| Stone Milling | Traditional method producing coarser texture. | 60-75% |

| Roller Milling | Modern method yielding fine, uniform flour. | 75-90% |

| Air Classification | Separates flour by particle size for consistency. | 70-85% |

By understanding these intricate techniques and selecting the appropriate equipment, millers can optimize flour extraction, providing high-quality maize flour that meets the diverse culinary needs of consumers. Each stage of the milling process plays a vital role in enhancing not only the flour’s quality but also its versatility in various applications, from baking to cooking.

Quality Control in Maize Milling: Ensuring Consistency and Freshness

In the intricate world of maize milling, maintaining quality control is essential for transforming the humble kernel into a premium flour product. This ensures that customers receive a consistent and enjoyable product with every batch, meeting both culinary and nutritional standards. To achieve this consistency, several key practices are employed throughout the milling process:

- Regular Testing: Frequent assessments of both raw maize and finished flour for moisture content, particle size, and flavor.

- Supplier Standards: Establishing strict quality metrics for maize suppliers to guarantee only the best kernels are selected.

- Batch Tracking: Implementing a system to trace each batch of flour from harvesting to packaging, ensuring accountability.

Freshness is another vital component of quality control in maize milling. Post-milling, the flour must be packaged in an environment that protects it from moisture and contaminants. A consistent monitoring system enables mills to manage inventory effectively, ensuring that only the freshest flour reaches consumers. The importance of this cannot be understated, as freshness directly impacts flavor, baking properties, and shelf like. Here’s a brief overview of typical freshness management strategies:

| Strategy | Description |

|---|---|

| Sealed Packaging | Using airtight containers to prevent moisture absorption. |

| Refrigeration | Storing flour in cool temperatures to extend shelf life. |

| FIFO System | Utilizing a first-in, first-out system for inventory to ensure older stock is used first. |

From Farm to Table: Sustainable Practices in Maize Flour Production

In the intricate journey of maize flour production, sustainable practices play a pivotal role in ensuring that each kernel contributes positively to the environment and communities involved. Farmers cultivate maize using methods that prioritize soil health and minimize chemical inputs, which ultimately leads to richer grains and healthier ecosystems. Some essential practices that embody sustainability in maize cultivation include:

- Crop Rotation: Alternating maize with legumes and other crops enhances soil fertility and disrupts pest cycles.

- Conservation Tillage: Reducing soil disturbance preserves soil structure and moisture, which promotes healthier crops.

- Integrated Pest Management: Utilizing biological controls and natural predators reduces dependence on synthetic pesticides.

Once harvested, the journey continues at the milling stage, where sustainable methodologies remain crucial. Mills that prioritize eco-friendly practices often implement energy-efficient technologies and waste reduction strategies. They are increasingly focusing on sourcing their energy from renewable resources to minimize their carbon footprint. The following practices highlight sustainable milling operations:

| Practice | Description |

|---|---|

| Energy Efficiency | Adopting machinery that uses less energy while maintaining high throughput. |

| Byproduct Utilization | Converting milling byproducts into animal feed or for bioenergy production. |

| Water Management | Implementing water-saving technologies during the milling process. |

By engaging in these environmentally-friendly practices, the maize flour industry not only contributes to sustainable development goals but also connects consumers with the broader agricultural ecosystem, enhancing the overall quality and integrity of the food on their tables.

Final Thoughts

As we conclude our journey through the intricate process of maize milling, it becomes evident that this age-old craft is not merely a means to convert kernels into flour. It is a harmonious blend of tradition, technology, and transformation. Each step, from selecting the perfect ear of corn to the final grinding of flour, tells a story of skill, precision, and respect for the grain that has sustained countless generations.

Whether you’re a commercial miller, a home baker, or a curious enthusiast, understanding the art of maize milling unveils a deeper appreciation for the food we consume. The next time you unseal a bag of corn flour or prepare a dish featuring maize, take a moment to reflect on the journey it undertook—an alchemical process that starts in a field and ends on your plate. As we celebrate the versatile maize, let us continue to explore and honor the traditions and innovations that shape our culinary landscapes. The world of milling is ever-evolving, and with each kernel, it invites us to partake in its rich narrative.